The costliest and most fragile element in a stamping die’s ball-bearing guidance system is the Retainer Cage which carries and secures the ball bearings in a predefined matrix arrangement. It’s estimated that 90%+ of all catastrophic damage to Retainer Cages (of the suspended / hanging-type) occurs during DIE HANDLING activities – especially during the process of “flipping” the upper die shoe assembly prior to conducting die maintenance / repair activities.

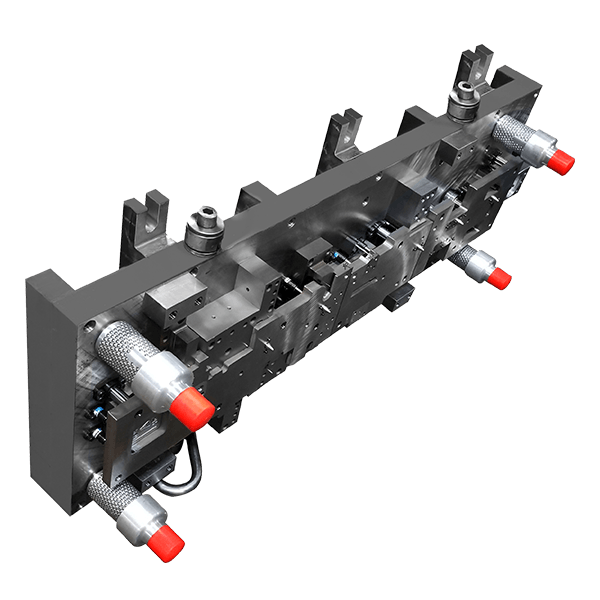

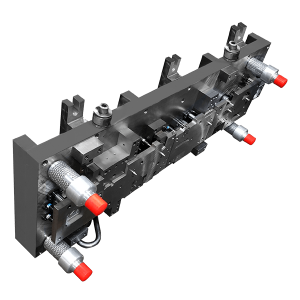

Superior Die Set Corporation is pleased to introduce CageSaver, a handy new diemaker’s accessory designed to virtually eliminate the possibility of Retainer Cage damage during die handling and maintenance activities. The CageSaver product is configured to work with inch- and metric-series products, all standard nominal diameters, and all current styles of suspended Retainer Cage designs (A-type / D-type / L-type ) currently available in North America.

Superior Die Set Corporation is pleased to introduce CageSaver, a handy new diemaker’s accessory designed to virtually eliminate the possibility of Retainer Cage damage during die handling and maintenance activities. The CageSaver product is configured to work with inch- and metric-series products, all standard nominal diameters, and all current styles of suspended Retainer Cage designs (A-type / D-type / L-type ) currently available in North America.

CageSaver’s clever and clean design maintains the Retainer Cage in a fully- and safely retracted position during all die handling activities. The Cage remains completely enclosed by a translucent polycarbonate sheath (optional) which shields the Cage and ball bearings from direct water / detergent impingement during pressure-washing of the die. No longer will diemakers need to resort to such crude, inexact measures as rubber bands, tape, nylon tie straps, twist-wire, etc. for securing Retainer Cages in a safe position during die handling activities. The CageSaver’s design also employs a rugged elastomeric pad which is provided for safe and cushioned resting / storage of the upper die assembly upon the toolroom floor or on a storage rack. The CageSaver configuration furthermore allows the upper die shoe to be securely rested upon the lower die shoe with the Guideposts fully disengaged from, but in-line-with, the Bushings in the lower shoe.