High Quality Manufacturing

With over 150,000 square feet of factory floor in Oak Creek, Wisconsin our impressive range of capabilities are backed by over 90 of years of experience serving the greater manufacturing industry. Our extensive manufacturing capacity allows us to rapidly respond to a wide range of projects, large and small. Explore below to learn more about how Superior Die Set can help you hold the timelines, tolerances, and budget on your next project.

-

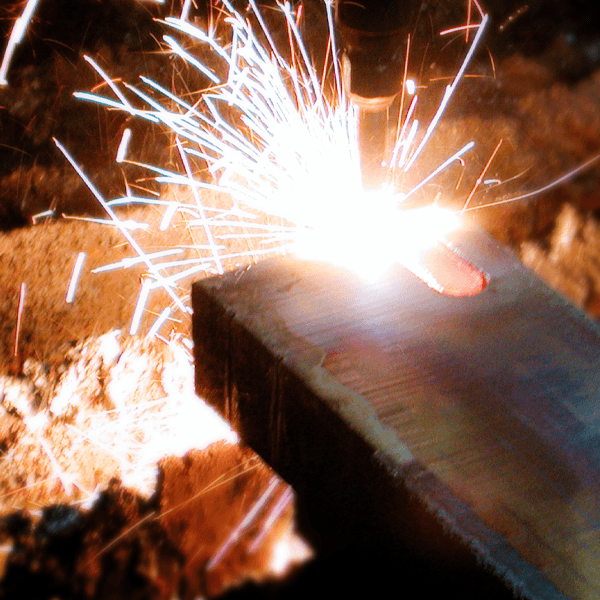

Torch & Plasma Cutting

Offering both Oxy and Plasma cutting on 5 different machines with full CNC controls and nesting software, Superior offers a range of cutting capabilities from 1/8” to over 12” thick. Shape cuts, burnouts, ramps, and more, are possible with precision not usually available on flame-cut steel plate. +/- .030″ is typical torch-cut tolerance on 2” thick plate. So let Superior start the spark on your next cut-plate project.

-

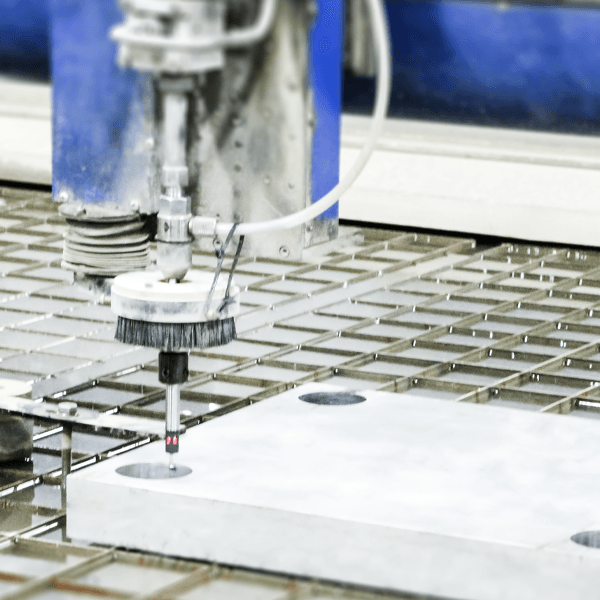

Water-jet Cutting

New Water-Jet Cutting at Superior offers a range of cutting material capabilities from Steel, aluminum, glass, copper and others on our 70″ x 140″ cutting table. Water-Jet Cutting specializes in such features as: +/-.005″ tolerance, intricate precision cut geometry and internal cut openings, with no heat affected cut zone.

-

Stress Relieving & Tempering

Our stress relieving oven is 4′ x 8′ x 16′, rail car design for easy load accessibility.

Tempering furnace available for our in-stock pre-hard alloy steels, to soften flame hardened edges.

Vibratory Stress Relieving gives unlimited size capabilities for special application not suited for thermal applications. The Acceleramator scans the structure of the fabrication from 0 to 6000 RPMS, then creates a chart identifying the unique stresses to that structure. The stress relieving process is vibrated at the stress points identified in the scan.

-

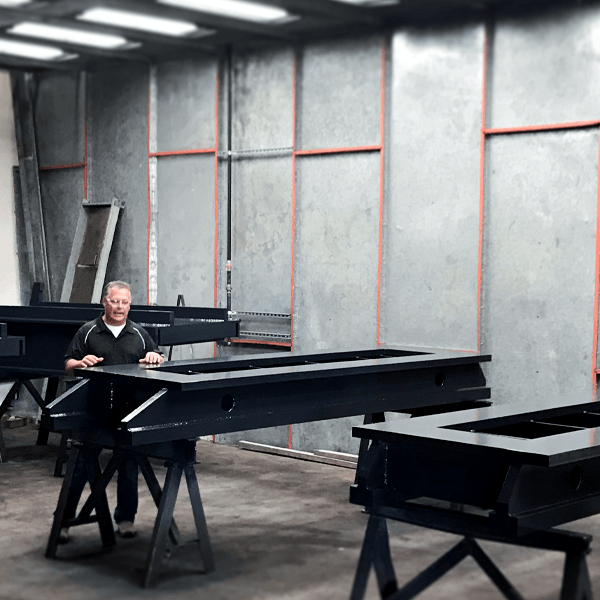

Welding

Our certified weld team is capable of MIG, TIG, Submerged arc, Carbon arc, and stick welding. Weighing up to 30 tons, weldments of steel plate and structural tubing are manufactured with filet welds up to 2 inches. Shot blasting is also available on-site for an optimal weld penetration. Leverage Superior’s welding with other in-house capabilities for your next fabrication project.

-

Painting & Shot Blasting

Our Paint Booth is 10’ x 30’ x 12’ tall and is designed to provide superior lighting with a clean & controlled ventilated work area for safe paint applications. Prime and finished painting application including: powder coating, and electrostatic which produces a smooth and streak-less finish.

Shot blasting is ideal for scale removal, pre-weld treatment and for prime and finished painting preparation. Shot Blasting is also available on-site for an optimal weld penetration.

-

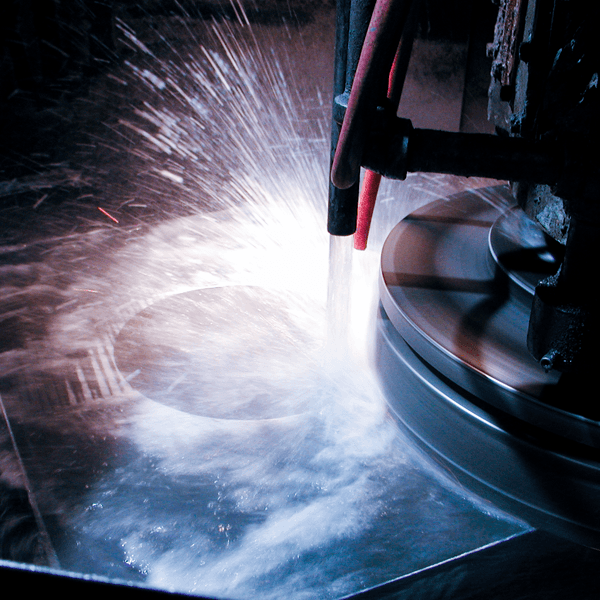

Grinding

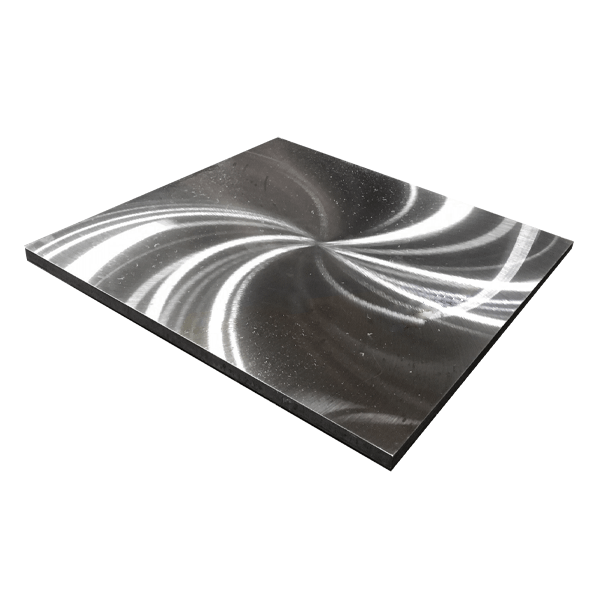

With over twenty grinding machines under one roof, Superior Die Set knows how to put the wheel to steel. Superior’s standard tooling tolerances assure your flatness, parallelism, and size requirements will be met. Multiple grades of steel and aluminum can be ground to your specifications. Blanchard (rotary) grinding is available with up to a 160” diagonal, along with surface (reciprocate) grinding up to 60” by 80”.

Cincinnati OD Grinders

Grinder 1: Max 15” long x 3.5” OD

Grinder 2: Max 28” long x 4.5” OD -

Cylindrical Grinding & Machining

Combining state-of-the-art machinery and workholding with toolmaker expertise, Superior Die Set offers an unrivaled lineup of Custom Die Component services, including:

-Between center, thru-feed and in-feed centerless grinding

-Internal and surface grinding

-Form grinding, honing, and hard turning of materials up to 65 Rc

4 & 5 axis machining, Wire EDM and small hole ED drilling-In-house Induction Hardening and Heat Treatment – in-stock selection of carbon and bearing steel, stainless, tool steel, high alloy, aluminum, bronze, and more

While we do make our own components in-house, we can make your custom designs as well!

-

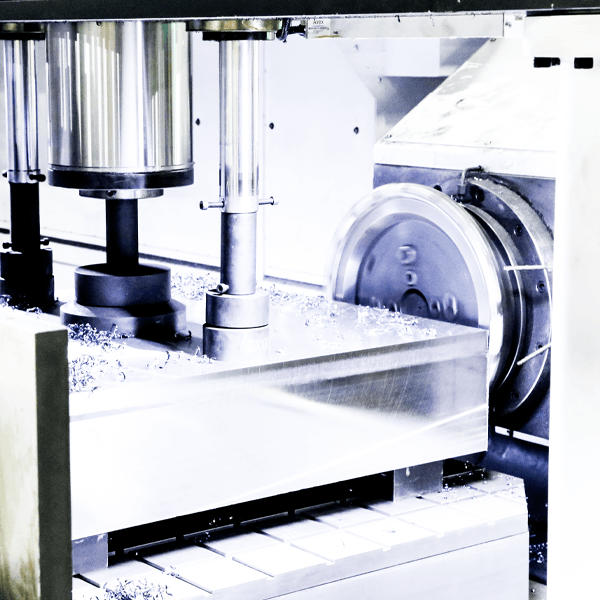

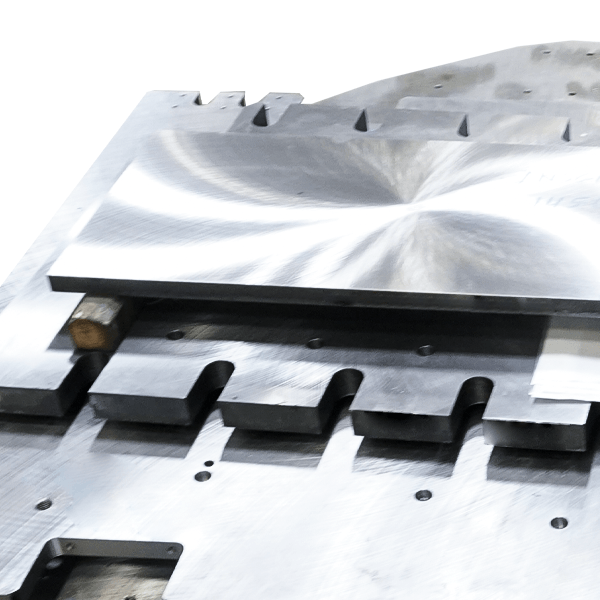

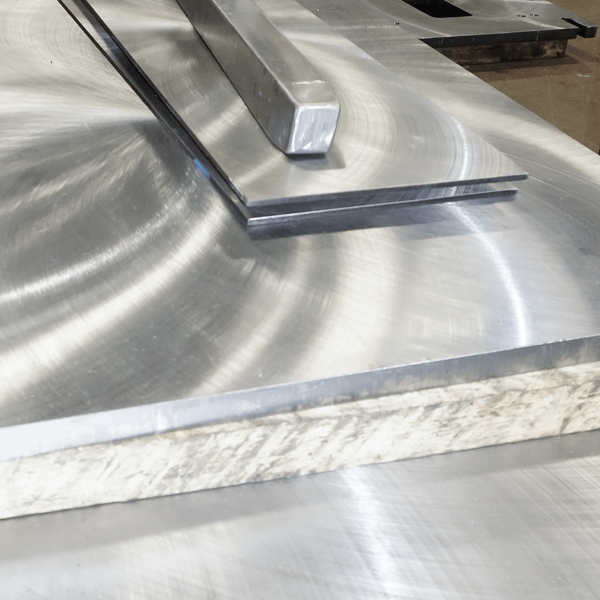

Dual Spindle Milling

Superior Die Set has four Quick-Mill’s that accurately machines multiple edges of plates to within .002” TIR with a size range of .125″ high x 800″ square up to a maximum of 16” high x 48” square. The dual spindle action rapidly removes material on two opposing edges, then indexes 90 degrees and completes the process so that all 4 sides are milled square and parallel. The micro finish produced by this machine is better than most ground finishes, typically surpassing 32 Ra. We can even square plates much larger than 48” on our typical horizontal centers.

Amada THV460

Max Material Dimensions: (W x L x H) 18.4″ x 18.4″ x 5.9″ (468 x 468 x 150 mm)

Max Machining Dimensions: (W x L x H) 18.4″ x 18.4″ x 5.9″ (468 x 468 x 150 mm)

Min Machining Dimensions: (W x L x H) 0.787″ x 0.787″ x 0.394″ (20 x 20 x 10 mm)

Table Loading Capacity (Max Workpiece Weight) 705 lbs (320 kg)Amada PMH1308

Max Material Dimensions: (W x L x H) 51.1″ x 31.5″ x 11.8″ (1300 x 800 x 300 mm)

Face Mill Cutter Diameter: Dia. 20.7″ (Dia. 525 mm)

Table Loading Capacity: (Workpiece + Magnetic Chuck) 7716 lb (3500 kg) -

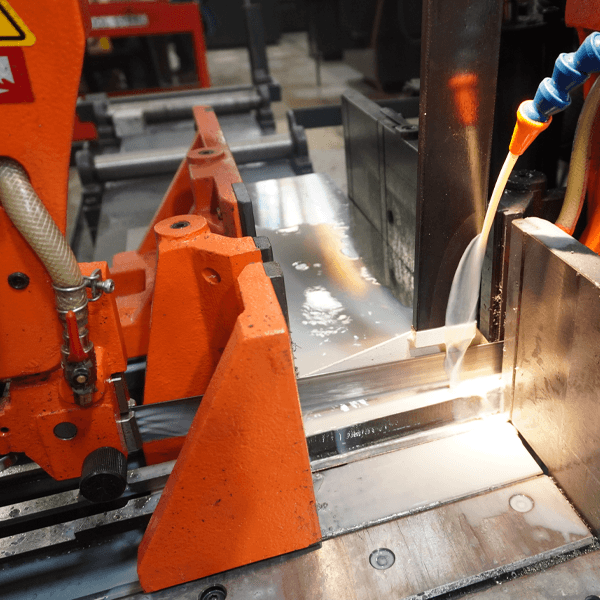

Saw Cutting

Superior Die Set has the capability to saw not only traditional steels, we can even cut aluminum. We have four Cosen automatic band saws and a HEM plate saw. For capacity information, please see below.

Cosen C-325NC

Capacity Round: 325 mm (12.8″)

Capacity Square: 325 mm (12.8″)

Capacity Rectangle: (HxW)325 x 380 mm (12.8″x15″)Cosen G320

Capacity Round: 325 mm (12.8″)

Capacity Square: 325 mm (12.8″)

Capacity Rectangle: (HxW) 325 x 380 mm (12.8″x15″)Cosen C-1000NC

Capacity Round: 1000 mm (39.4″)

Capacity Square: 1000 mm (39.4″)

Capacity Rectangle: (HxW) 1000 x 1000 mm (39.4″x39.4″)HEM 18/144 Band Saw

– Traveling Head

– 18″ Throat

– 144″ Traveling Length

– 12″ Height

– Table Size 4′ X 8′ -

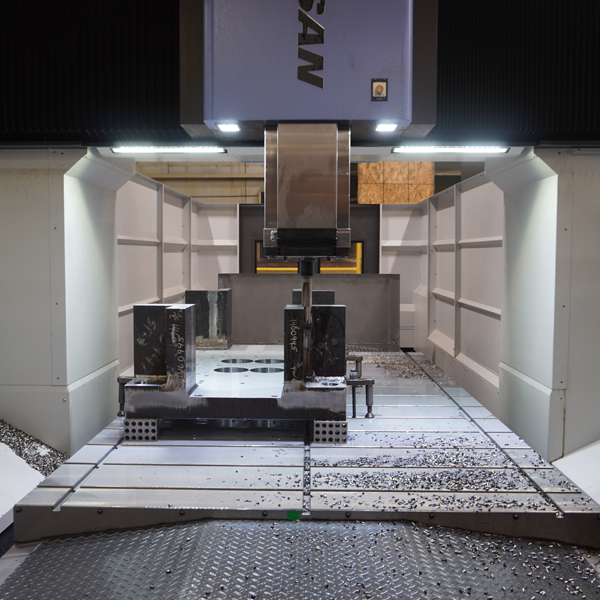

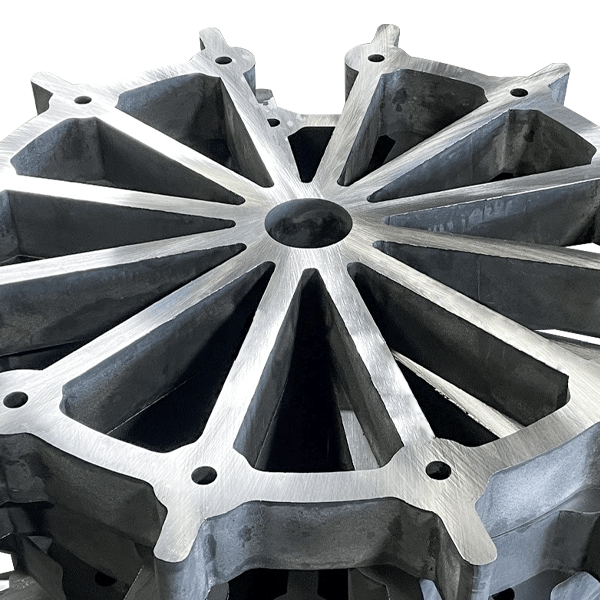

Special Machining

Housing over 25 machining centers – with vertical capacity up to 22′ long, and horizontal capacity up to 98″ x 206″. Superior can perform a spectrum of operations like pockets, key ways, drilling and boring to the strictest of tolerances. With our gun-drilling capabilities, deep holes can be drilled up to 39″.

-

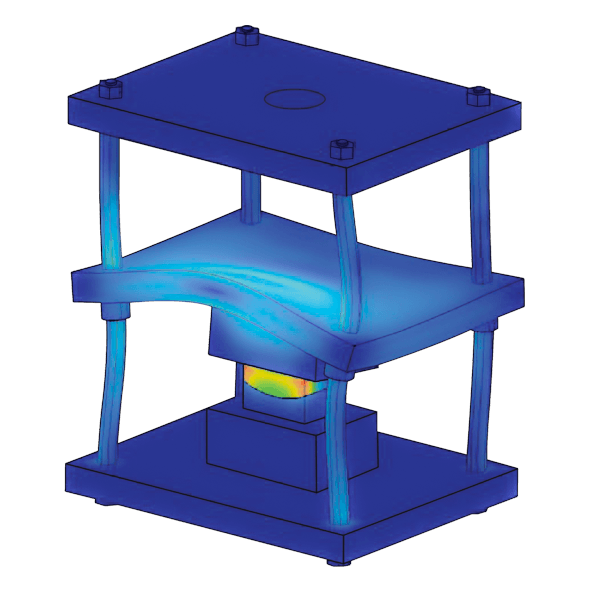

Engineering Services

Draw on Superior’s over 90 years of diverse manufacturing experience to assist you with product design and development.

-Mold Flow Analysis featuring Exaflow® Tunnel Gates

-Design assistance for the Threadformer™ Unscrewing device

-Multi-platen design parameters including Finite Element Analysis (FEA)

-Forging press bolster and trim die design assistance

Reliable Materials

Superior Die Set Corporation uses only quality materials to make products stronger and more reliable.

-

A36MOD Steel (Up to 12″)

A modified A36 steel with a restricted carbon range that is centered on 1020. It is a hot-rolled mild steel with greater tensile strength than typical low-carbon warehouse steels. It has consistent machinability permitting economic stock removal.

Available Thicknesses (in)

1⁄4, 3⁄8, 1⁄2, 5⁄8, 3⁄4, 7⁄8, 11 1⁄8, 1 1⁄4, 1 3⁄8, 1 1⁄2, 1 5⁄8, 1 3⁄4, 1 7⁄8, 2

2 1⁄8, 2 1⁄4, 2 3⁄8, 2 1⁄2, 2 5⁄8, 2 3⁄4, 2 7⁄8, 3

3 1⁄8, 3 1⁄4, 3 1⁄2, 3 3⁄4, 4

4 1⁄4, 4 1⁄2, 4 3⁄4, 5

5 1⁄4, 5 1⁄2, 5 3⁄4, 6

6 1⁄4, 6 1⁄2, 6 3⁄4, 7

7 1⁄4, 7 1⁄2, 8

8 1⁄4, 8 1⁄2, 9

9 1⁄4, 9 1⁄2, 10

10 1⁄4, 10 1⁄2, 11

11 1⁄4, 11 1⁄2, 12

-

FORTAL® Aluminum (Up to 8″)

This exclusive 7000 series aluminum alloy offers high-strength properties, yet maintains exceptional machinability. Low-residual stress and modulus of elasticity prevent premature deformation. Its uniform cross-section is harder than mild steel. The thermal conductivity being greater than steel along with excellent polishing characteristics, make Fortal a good choice for plastic mold and other tooling uses.

Available Thicknesses (mm)

14, 18.5, 22.5, 28, 35.5, 39, 43.5, 46, 53.5,

65, 72, 82, 92, 102, 127, 162, 182, 202 -

4140 as Rolled Steel (Up to 4-1/8″)

An AISI 4140 Chrome Moly alloy steel supplied at 22-26 Rc (245 BHn) typical. This hot-rolled steel provides vastly Superior mechanical properties in comparison to typically used A36 plate with economical value against prehard alloys. Stocked in 1/8″ oversized thicknesses up to 4.125″.

Available Thicknesses (in)

1 1⁄8, 1 3⁄8, 1 5⁄8, 2 1⁄8, 2 5⁄8, 3 1⁄8, 4 1⁄8 -

4130 Prehard Steel (Up to 9-1/8″)

An AISI 4130 alloy steel that is supplied heat treated to 300 Bhn (262-321). This holder block quality type of steel has an optimum balance between machinability and hardness while possessing excellent qualities for retainer and backup plate applications.

Available Thicknesses (in)

7⁄8, 1 1⁄4, 1 1⁄2, 2, 2 1⁄2, 3, 3 1⁄2, 4, 4 1⁄2, 5, 6, 7, 8 1⁄8, 9 1⁄8 -

FORGE-RITE™ 4340 Steel (Up to 12-1/8″)

This hot-rolled 4340 alloy steel is a proprietary material specially formulated for the manufacture of forging equipment and tooling. It is a tough, shock-resistant nickel-chrome-moly steel with optimum grain flow characteristics. It is supplied “stress relieved” at 215-255 BHN with improved machinability. Typical applications include those with severe impact, heat, wear and stress.

Available Thicknesses (in)

1 1⁄8, 1 5⁄8, 2 1⁄8, 2 5⁄8, 3 1⁄8, 4 1⁄8, 5 1⁄8, 6 1⁄8, 7 1⁄8, 8 1⁄8, 9 1⁄8, 10 1⁄8, 11 1⁄8, 12 1⁄8 -

P-20 Steel (Up to 6″)

A premium AISI 4130 alloy steel with reduced sulfur for cleanliness and excellent polishing ability. Supplied at 300 Bhn (262-321), this P20 type steel offers consistent machinability while maintaining superb mechanical properties.

Available Thicknesses (in)

1, 1 1⁄2, 2, 2 1⁄2, 3, 3 1⁄2, 4, 5, 6 -

TOOLOX® 44 (Up to 5-1/8″)

A low carbon premium alloy steel designed to have high-impact strength (Charpy tested @ 20 ft. lbs.) and low-residual stresses and therefore good dimensional stability. At 45 HRc, this steel can be readily machined compared to steels of like hardness. Toolox 44 is formulated to ERS properties and can be polished to a LENS quality finish.