An inspiring, rich and extensive story of family and manufacturing...

The incredible story of Superior Die Set starts with Polish immigrant Kasimir Janiszewski. At the tender age of 22, Kasimir choose to leave Poland to start a new life in the land of opportunity – the United States of America. He entered the U.S. via Port of New York in 1910. When asked about his specialty for immigration registration, he replied, “What specialty brings in the most money?” The immigration specialist answered, “tool and die maker.” Thus, with that, Kasimir entered the field of tool and die.

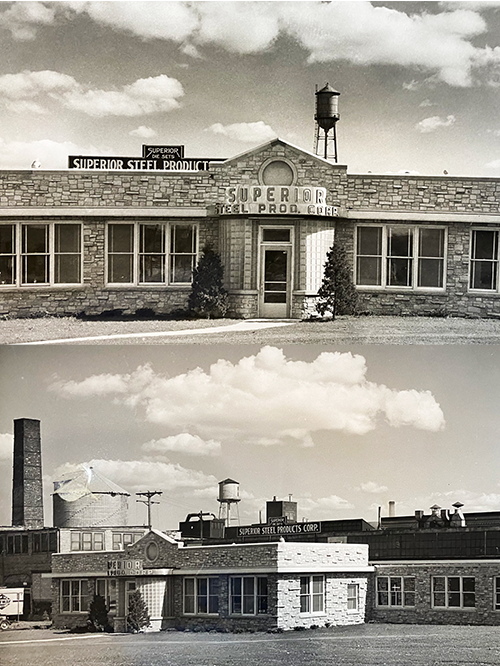

In 1923, Kasimir, alongside two partners, founded Superior Tool and Die, a business that focused on steel products and cast die sets, just outside the bustling city of Milwaukee. Kasimir’s prowess as a blacksmith earned him a reputation in the Milwaukee area for his mastery of die-drawing.

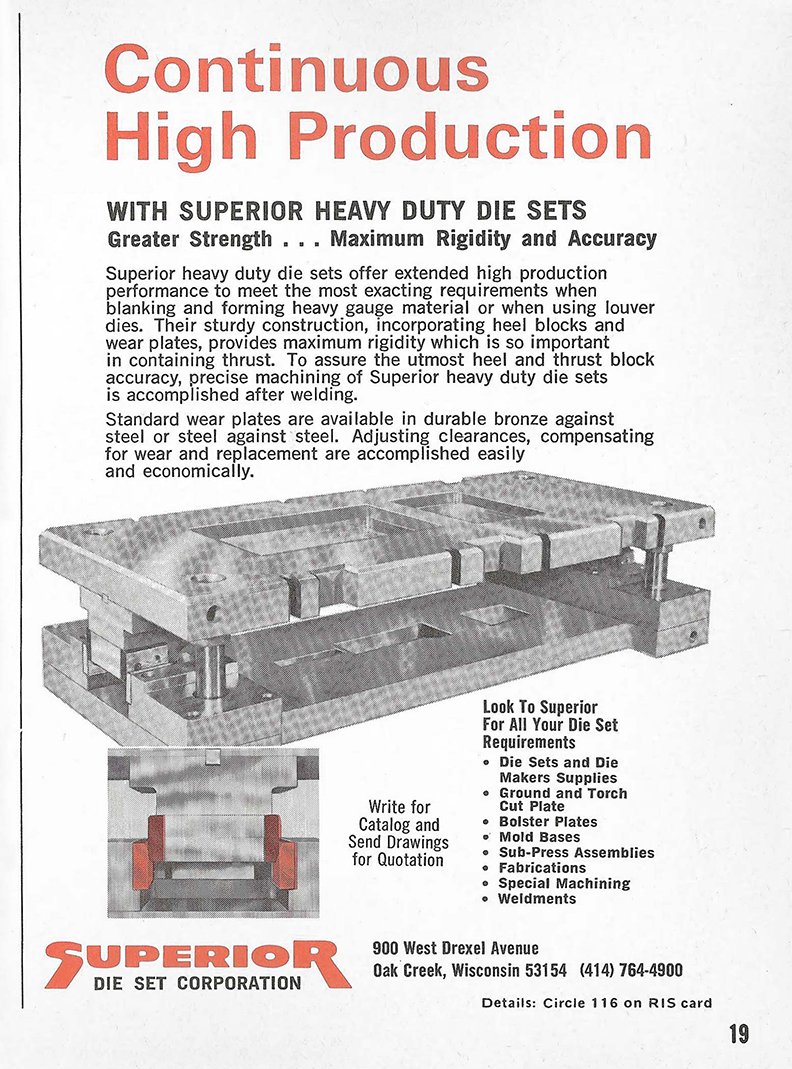

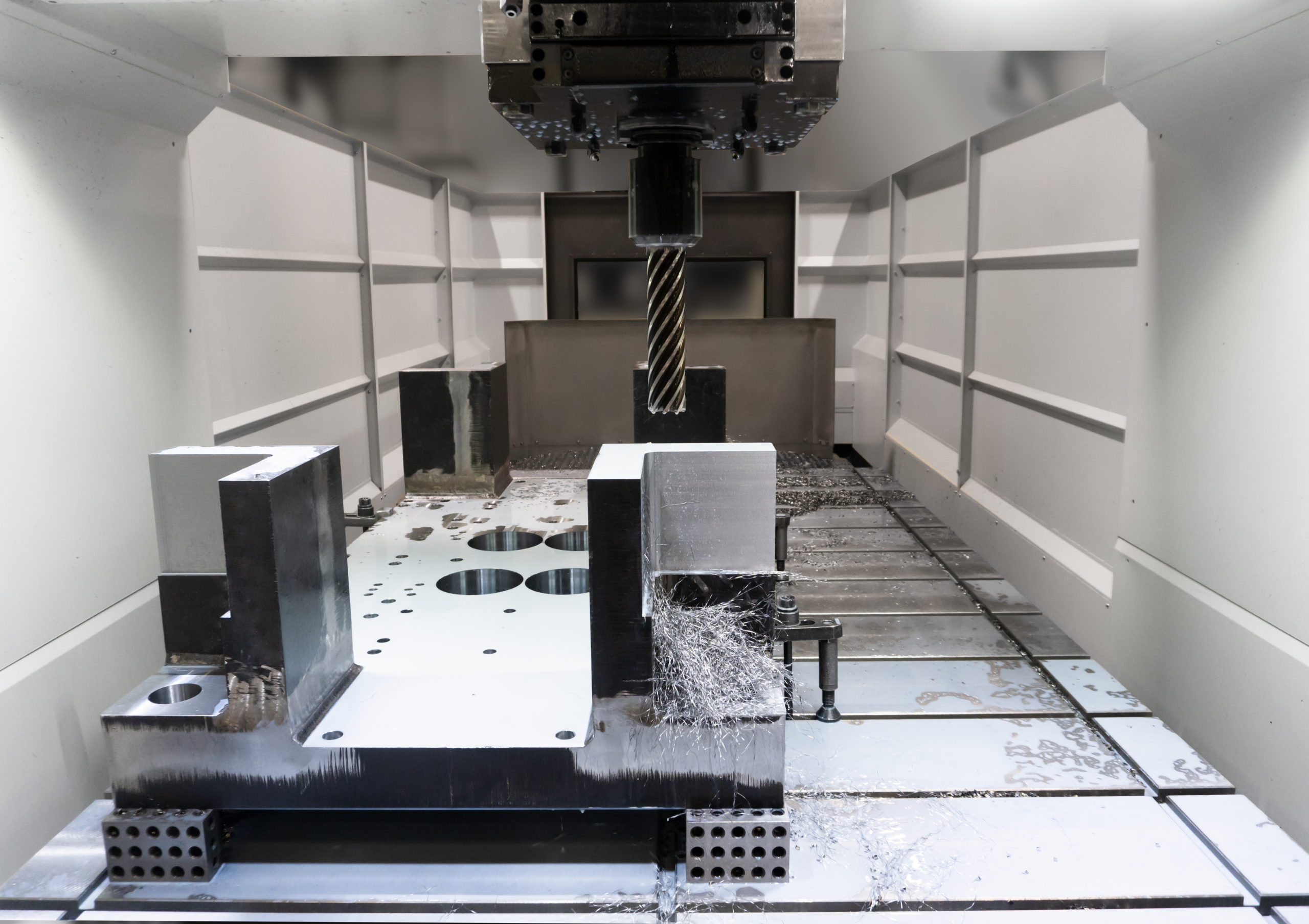

During the early years of business in 1928, Kasimir revolutionized the way die sets were manufactured by introducing an air-reduction torch (aka flame cutting) as an alternative to cast die sets, which could take months to produce. Kasimir was a true innovator and earned over 20 patents related to the tool and die industry over the next 50 years.

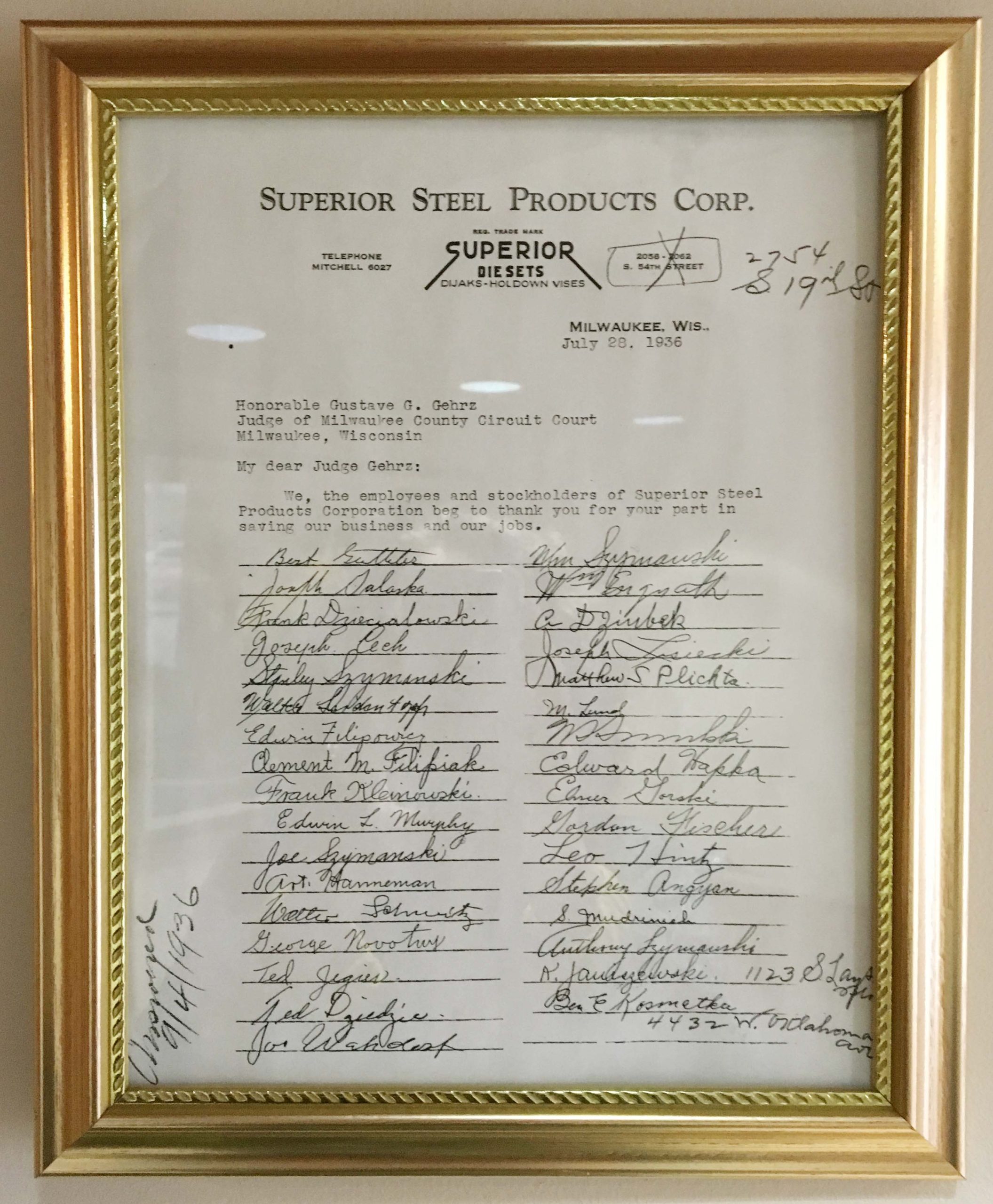

The Great Depression took its toll on many tool and die industries in the 1930s, causing a sharp decline in supply and demand. Yet, Superior Tool and Die was lucky enough to escape this devastating fate, thanks to Hope Dispensing’s generous order with money down – an unprecedented move that saved the company.

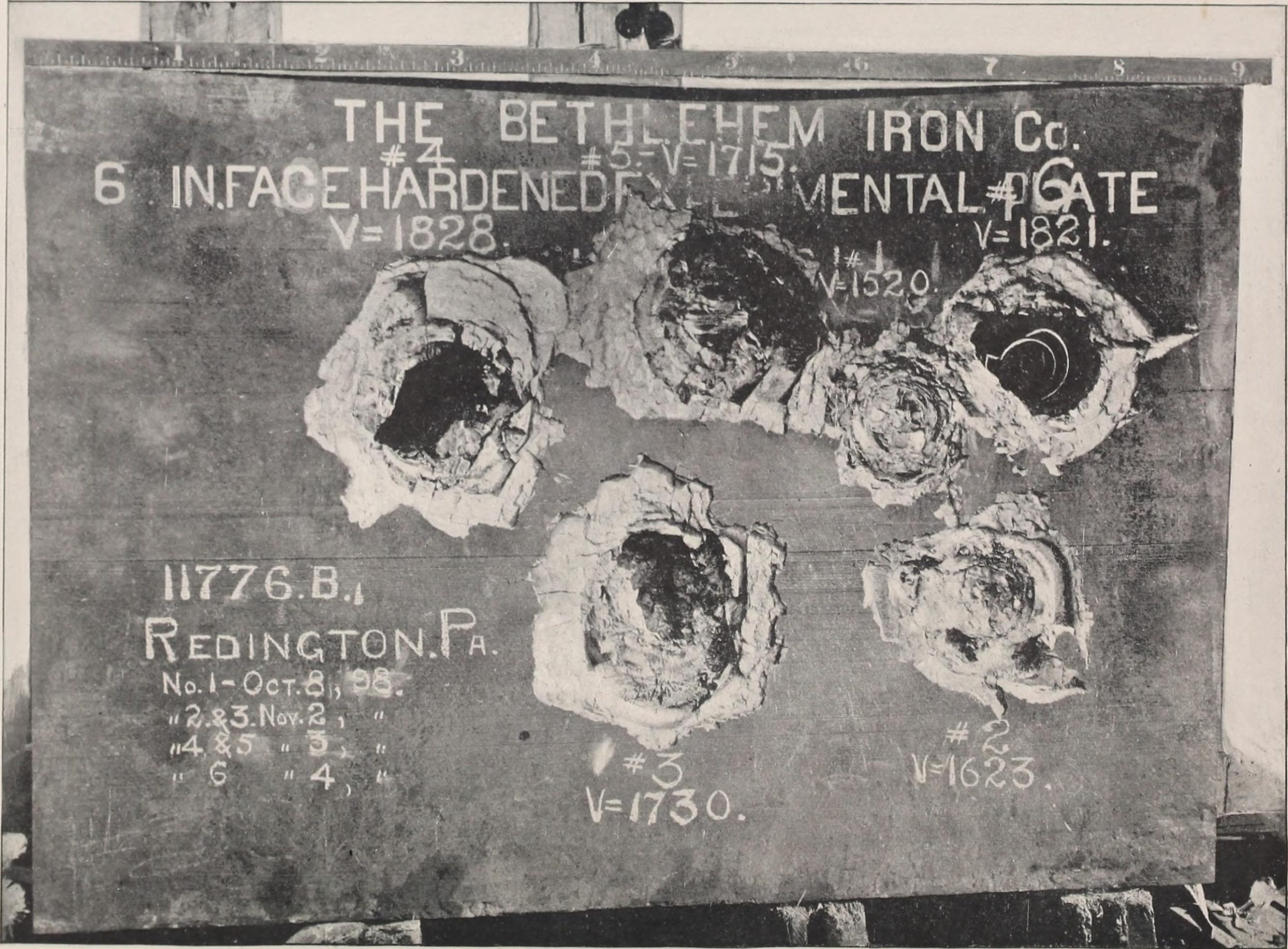

When the Second World War began in 1939, Superior Tool and Die created a prototype turret for the M1 Stuart. Meanwhile, Kasimir’s sons Alphonse (Army) and Casimir H. (Navy) enlisted in the military to battle the Axis powers. While Kasimir’s sons served in the Armed Forces, he sold the tool and die portion of the business to his two original partners; forming Service Tool (which still exists today). Kasimir kept his portion of the die set business and renamed it Superior Steel Products, and the two companies began their new independent lives. They continued to share the same building they opened in until Service Tool moved to a West Allis, Wisconsin facility, making their story even more exciting.

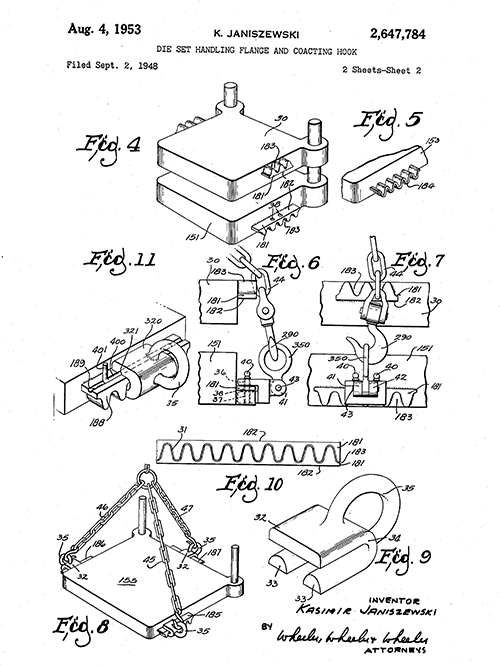

In 1954, Kasimir revolutionized the die set industry with his invention of ‘Finger Flanges’, a patent that allowed for the easy movement of heavy dies. Before this innovation, die manufacturers had to manually move these pieces, as opposed to using cranes like they do today. Kasimir’s invention undoubtedly made an immense impact on the industry—one that continues to be felt today.

During the ’60s, Superior Steel Products was flourishing, resulting in the company splitting into two separate entities. Edward Janiszewski opened another branch in Plainville, Connecticut, while Casimir H. and Alphonse took the reins of the Wisconsin facility.

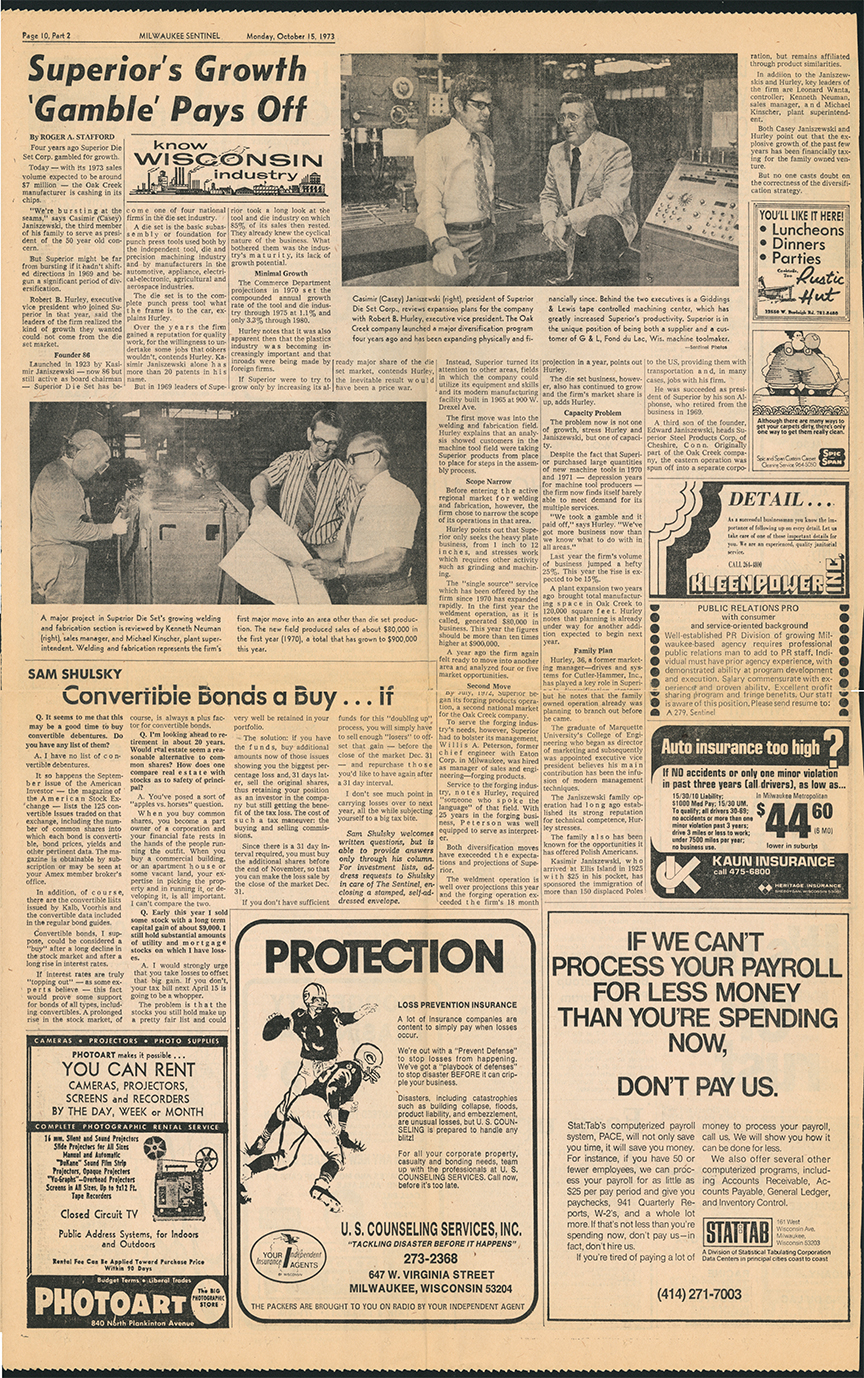

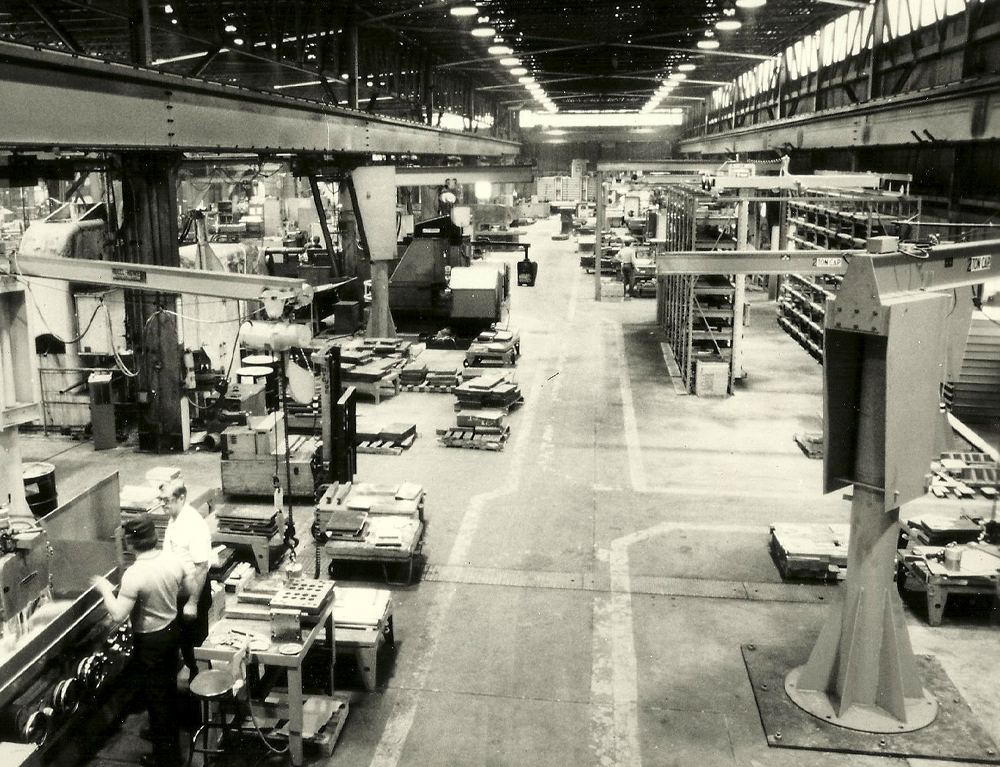

Casimir H. and Alphonse made the decision to rebrand the company and move to the current facility – Superior Die Set Corporation, Oak Creek, WI. Following this relocation, Alphonse was appointed President of Superior Die Set Corporation and held the role until 1969, with Casimir H. taking over afterwards. This is where the paths of Superior Steel Products and Superior Die Set went in separate directions for good.

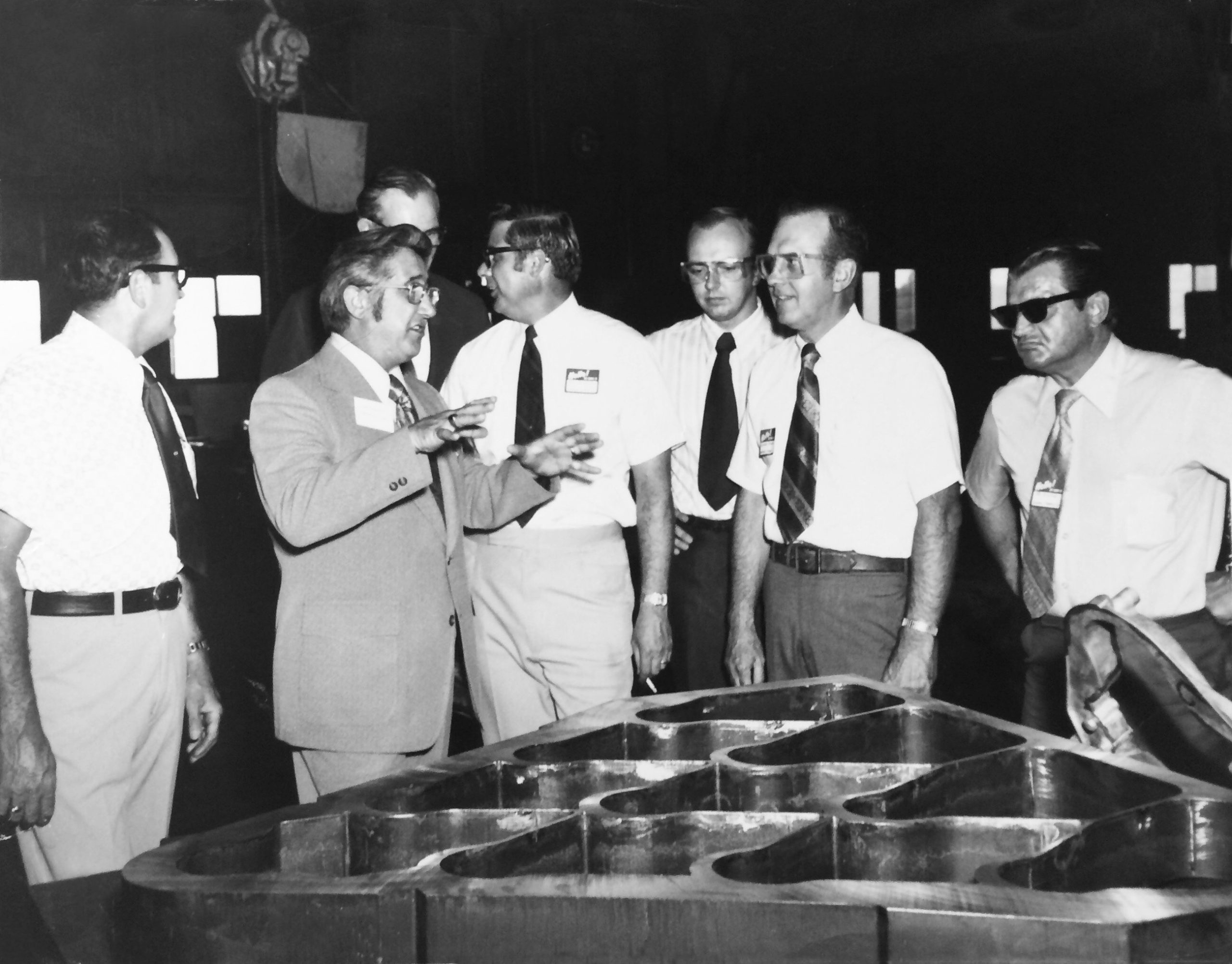

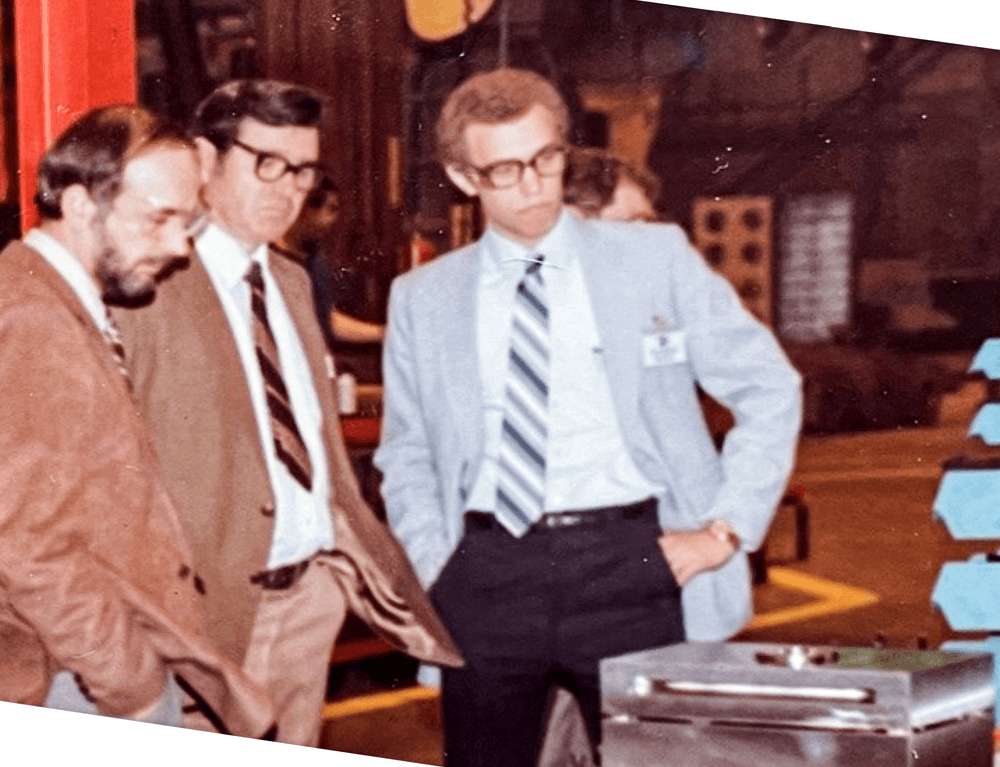

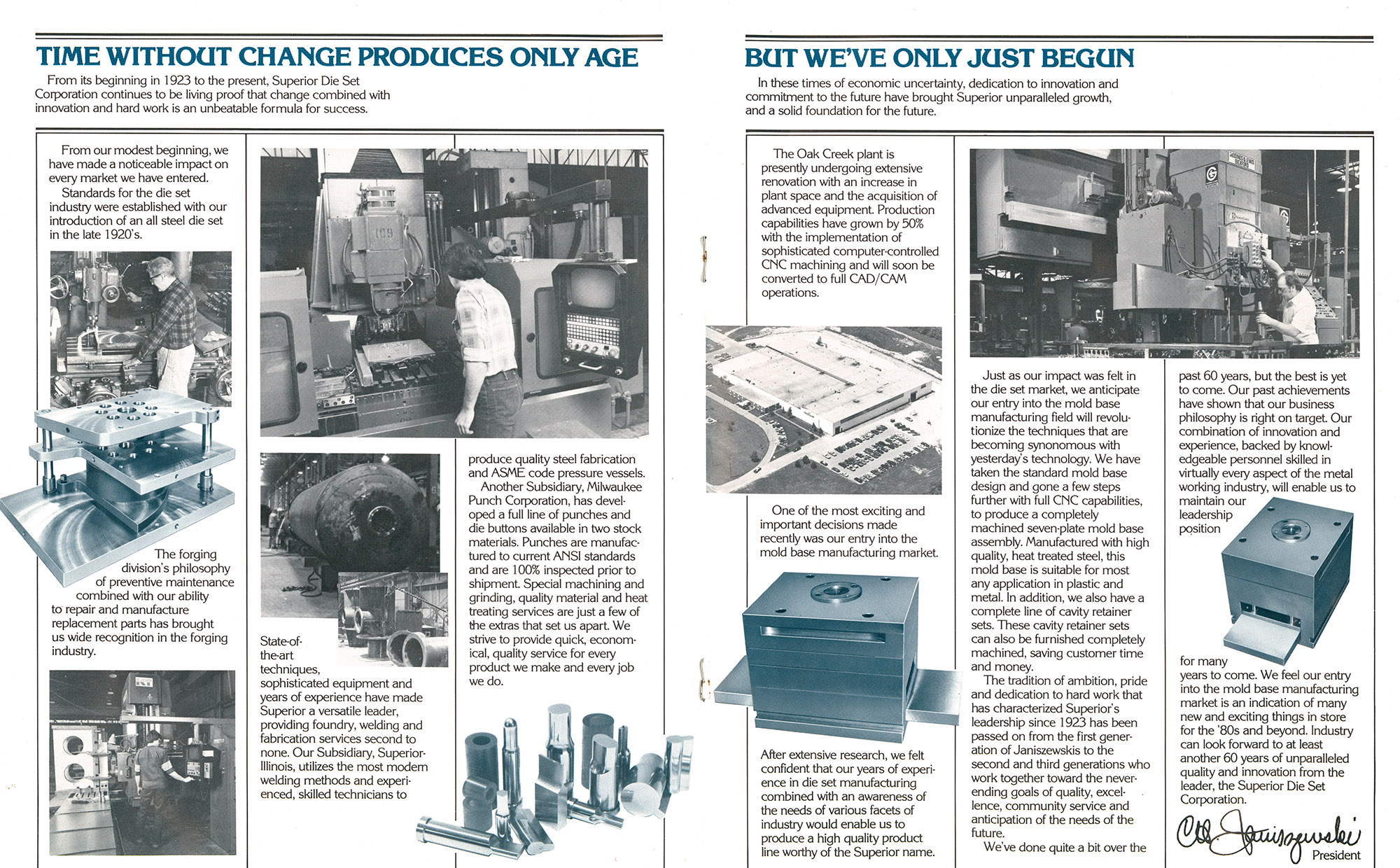

Superior Die Set continued to expand business opportunities; in the 70’s, Superior purchased another facility called Superior Illinois, expanded its facility to include a welding bay in 1971, entered the Forging Division Industry in 1972 and lastly, founded Milwaukee Punch Company in 1973.

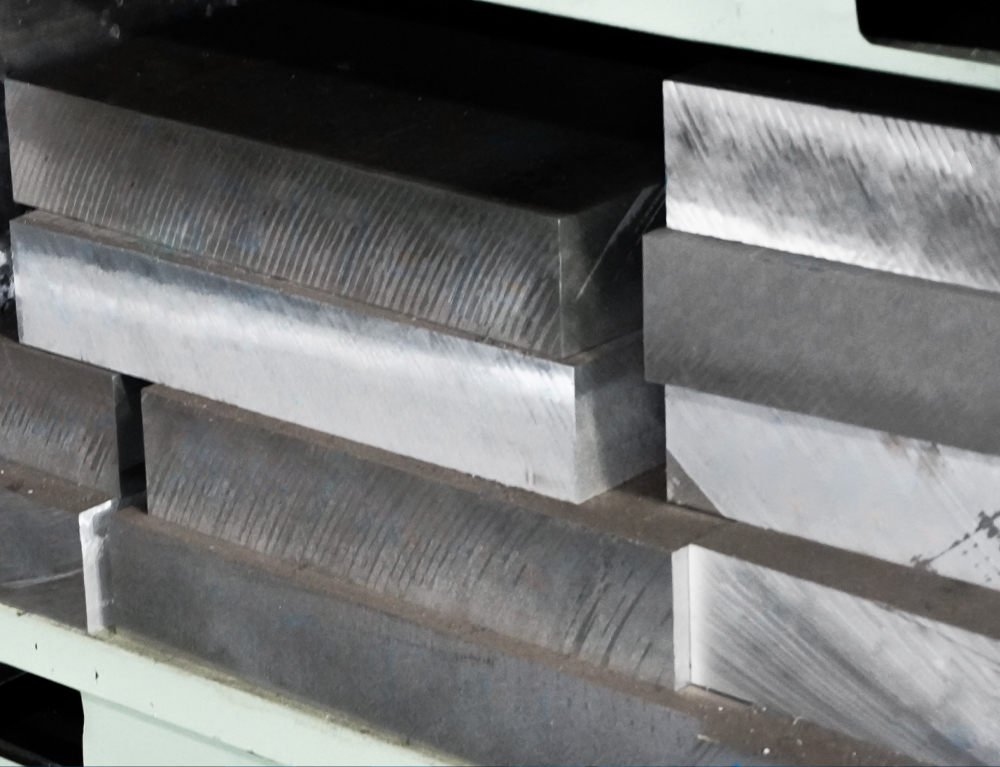

Later in the 1980’s, Superior signed a distributor’s agreement with a French company, Pechiney, to distribute an aircraft-grade aluminum alloy called Fortal, specifically designed for the stamping industry. Superior Die Set would drastically change the die set industry by becoming the first company to embrace aluminum in die sets.

In 1982, Superior Die Set underwent massive foundational change and factory construction. Expanding to accommodate the new market entry in the Mold Base Division. Superior stayed true to their core values as they continued to expand their offerings and capabilities.

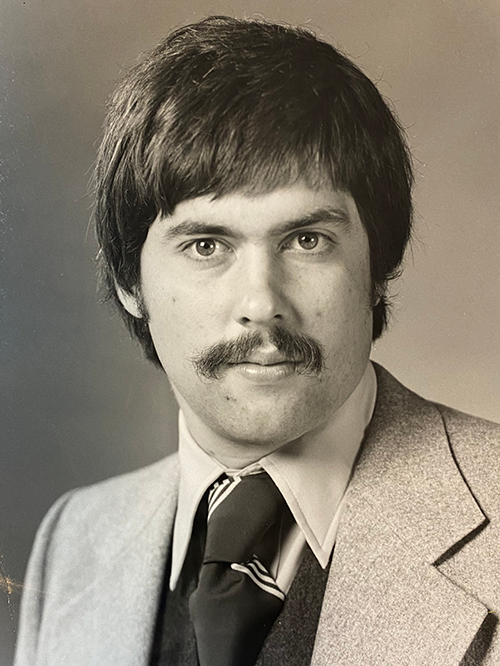

In 1988, Casimir S. Janiszewski (oldest son) took over his father Casimir H.’s role as CEO and President of Superior Die Set. As a passionate proponent of Polish heritage, Casimir S. had a burning ambition to visit post-communist Poland and find a suitable Polish components supplier to support their production back in Wisconsin. In 1993, his dream became a reality when Superior Die Set acquired FCPK “Fabryka Części Precyzyjnych Kazimierz (Kasimir’s Precision Components Factory)” Bytów.

In the early 90’s, Superior Die Set made huge strides for process improvements by expanding the building to the northwest to include a larger engineering facility. Additionally, in 1993, Superior continued to rise in the Mold Base industry by obtaining exclusive rights to distribute the Slide Locks.

In 1999-2000, Superior began major upgrades to planning, scheduling, and manufacturing by implementing a new ERP system. This changed operations drastically, virtually making the shop paperless. Additionally, in the era, Superior Die Set’s sister company Milwaukee Punch Company rebranded itself to Greendale Precision Services (GPS) in 2008. Also, Superior’s Polish sister company FCPK Bytów experienced so much success in the 2000’s that they opened a 2nd plant in Kielce, Poland in 2002.

In 2013, Superior elected Frank Janiszewski (CHJ’s middle son) as CEO and president. Frank continued as the third generation of J’s at Superior, staying true to the family-owned and operated business values.

Not to long after Frank became CEO and President of Superior, the fourth generation of Janiszewski’s joined the family business. Nick Janiszewski and Steve Janiszewski (Son of Casimir S. Janiszewski) began their careers at Superior, as well as Jake Janiszewski (Frank Janiszewski’ s son).

2019 was a momentous year for Superior. To foster further growth in the next generations of manufacturing, Frank Janiszewski employed Superior’s first non-family CEO, Martin Girga. Martin’s principal task was to introduce the company’s mission, vision, and core values – laying the groundwork for operational upgrades and investments into new technologies.

2020, a year plagued by the pandemic of COVID-19, Superior acted swiftly. Its Sister Company Greendale Precision Services (GPS) moved into the Superior Die Set facility, and FCPK Bytów rebranded itself to ProPlastica. Sensing the need of the hour, Superior manufactured a mold base to mass-produce a component of N95 masks. Through this initiative, Superior Die Set enabled communities to stay safe and kept their factories running.

Superior kept true to their vision, mission, and core values in 2021 by making considerable investments into new machinery, technology, personnel talent, and acquisition. Additionally, they went through a major renovation of their front office, unifying all departments as one ‘Superior’ team.

2022 to present, Superior launched its first ever ‘Employee Engagement Committee’, a group focused on operational improvements and engagement activities. Additionally, Superior makes plans surrounding innovative ideas and growth initiatives to commemorate the 100th year anniversary (in 2023).

Scroll below for a timeline of our highlights.